Robot Production Line with 3D Vision

The highest possible level of automation

Environmental legislation is driving a move towards low emission electrical propulsion for ferries and other vessels. With its new factory in Trondheim, Norway, Siemens is addressing the rapidly growing demand for maritime batteries. In a highly-automated production line engineered by system integrator Intek, Zivid’s 3D machine vision camera played a vital role in optimizing production efficiency.

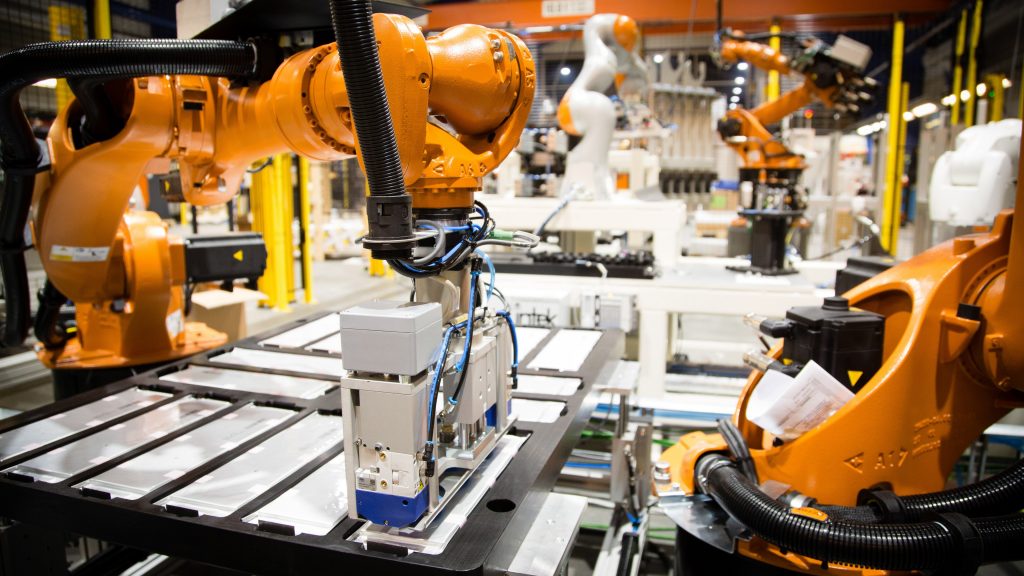

For the depalletizing cell, system integrator Intek chose to use the Zivid One real-time 3D machine vision camera, mounted on a Kuka KR9 robot arm, equipped with a custom designed vacuum gripper. (Bild: Siemens AG)

Siemens‘ Trondheim maritime battery production line is equipped with eight independently configurable robot cells, and seven automatic guided vehicles (AGVs) for handling inter-cell logistics. Designed and engineered by Intek over a 12-month period, the line handles everything automatically, from the initial picking of component parts through to final battery testing and documentation. For the vitally important depalletizing cell, system integrator Intek chose to use the Zivid One real-time 3D machine vision camera mounted on a Kuka KR9 robot arm equipped with a custom designed vacuum gripper. A Siemens programmable logic controller and a high-speed industrial PC provided control and processing power. Olaf Pedersen, Project Manager at system integrator Intek, explains the rationale, „By harnessing the Zivid One camera’s high-quality 3D point cloud we were able to easily pinpoint the outline of the pallet or tray, very accurately determine the outer dimensions of the component within, and then pick&place accordingly with the highest degree of accuracy. And being able to rely on a single camera snapshot meant it was very fast too.“ „By taking this more pragmatic approach we could resolve the issue of random component alignment without the need for any mechanical ’steering‘ systems or operator intervention to straighten up the components and shift them to predefined positions. What’s more, it also avoided the need for intensive programming of complex component CAD files. It’s a very flexible and reliable solution as a result.“ As well as ensuring a reliable pick,, the Zivid One camera-based machine vision system also ensures a highly accurate place, a performance criterion of vital importance to the efficiency of the interconnected production cells as Pedersen elaborates: „Because the robot arm is automatically stacking component parts onto a relatively small AGV it’s essential that the system takes into account distribution of load – the AGV needs to stay perfectly balanced in transit. Furthermore, when the AGV arrives at its destination production cell, the component parts need to be picked by another robot from predefined positions. And so accurate component placement onto the AGV was also essential.“ Norway’s earliest adopter of the Zivid One 3D color camera technology, Intek applied its own custom-designed software algorithms to manipulate the camera’s 3D point cloud data and maximize production line throughput.

Increasing Production Capacity

The advanced cellular nature of Siemens‘ maritime battery production line enables it to flex its capabilities and increase its production capacity in response to the expected upsurge in worldwide market demand and rapid technological developments. Battery design and production is more easily tailored to match a particular vessel’s function and duty cycle. By harnessing state-of-the-art machine vision, robotics and AGVs the Trondheim production line has achieved the highest possible level of automation, requiring only three people to work in the production area. It makes it possible to produce sustainable energy solutions more efficiently and cost-effectively. Of particular importance, the specific use of Zivid’s 3D machine vision camera in the component depalletizing cell has played a major role in assuring the necessary high production throughput. The camera’s high quality color 3D point cloud enables the robot arm to accommodate changes in product without the need for mechanical system modifications or intensive software redevelopment. With its highly-efficient, end-to-end automated production line Siemens is expected to be able to supply batteries for 150-200 ferries annually, equating to a battery module capacity in the order of 400 MWh. The factory can produce the battery modules needed for an all-electric ferry in less than four days. The positive environmental impact of the switch away from diesel powered vessels towards all-battery or hybrid powered vessels cannot be underestimated. Reductions in CO2 and NOx gas emissions and water-borne noise pollution will be felt globally as well as locally. Emission-free, near silent maritime operations are a worthy goal to aim for.